-

Posts

5921 -

Joined

-

Last visited

-

Days Won

65

Content Type

Profiles

Forums

Gallery

Posts posted by forteh

-

-

hello there

Well on my rear hydrolic rim brake the pad on the left is having trouble moving out and gripping the rim it just twitches, soooo does anyone no what could be rong with it ?

cheers

Learn to spell first

Youre getting a lazy piston on the one side, search the wiki on here for fixing lazy pistons and all should be revealed. Chances are its a combination of dirt in the seals and the tpa being wound right in.

Back the tpa off, take the slaves off and clean them thoroughly, rebleed if necessary, put it back together and reset the pads with as little tpa adjustment as possible.

Alternatively if you have a water bleed then you probably just need to drop a spot of oil on the outsides of the piston to lubricate the seals, but then if you have a water bleed you should know how to cure lazy piston

-

I already have dude.

Doh! So you did LOL

Was a good guess from me, my excuse was I was tired and it was past my bedtime on a school night

-

i said tap to m6 then helicoil to m5, when did i say anything about the above?..

didnt say you need an m5 helicoil tap, i said you need to helicoil it down to m5, which is the standard magura size, because when i first did it i went for m4, because that was the size of the bolt head, and thats what people get confused about.

Mat

What he means is that the tap for an M5 helicoil is not necessarily an M6 tap

My M6 helicoil kit has a 6.3 tapping drill supplied with it, now thats part way between the recommended drill for M7x1.0 (6.0mm) and M8x1.25 (6.75mm) so its almost as if its an M7.5 tap, not just the next size up.

At a rough guess I would say that the tapping drill for an M5x1.0 helicoil is about 5.2mm, perhaps someone can confirm this

-

When the red pads have died I may well try the necos

I will just carry some tar around with me in the mean time, cant be arsed with grinding all the time.

-

Just started getting back into riding trials after a 2-3 year hiatus due to cracked frame and neither funds nor inclination to start again.

Bought nick woods old hifi frame, a mono trial, heatsink cnc reds and cloud9 bash and started out again

Now being almost 29 my body isnt quite as pliable as it was 5 years ago, muscles are aching, tendons are burning and it all generally seems much harder to do than I seem to remember

(when I were a lad and all that bollocks

(when I were a lad and all that bollocks  )

)My main question is: -

Having been out tonight for a bit of a play around my rear brake has been needing a LOT of force to hold and the bite hasnt been what it was last week - the only difference is that most of the tar (which was applied to get the old koxx browns working till the reds turned up) has now worn off and I now just have a very, very dull grind. Chances of my brake finger simply not being strong enough or need to sort braking surface?

Bearing in mind I typically dont ride in the wet and Im about 90% street should I just put a fresh grind on the rim (4 year old tryall has had previous grinds) or just bung a touch more tar on? In my experience with this rim it doesnt hold a sharp grind for long and being a lazy bugger I cant be arsed to grind every other month, where as Im quite happy to carry a small blob of tar about with me and I have a big block of the stuff

So the choice is a smear of tar or a new grind?

Also would the brake be likely to bite better with a booster or without? Hold isnt quite as important as Im only 11-12 stone at most and dont go that big but got solid bite is reassuring. With my echo control booster the flex is minimal but perhaps some flex of the frame is required to provide bite and hold? I dont know, what are peoples experiences with and without also bearing in mind pad life and performance

For information the brake is water bled HS33 with an RB lever, echo control booster and heatsink cnc reds - pads are square and both hit the rim at the same time. Rim is a tryall with a very dull worn out grind.

Peoples opinions, thoughts and experiences would be appreciated

Beers in advance

-

He's got it

Great tune

Youre wrong, its f**king great tune

No wait, Im wrong its a f**king great album

-

Nice.

What song is that?

Venetian snares, with a very odd name - masodik galamb?

Cant be arsed to trawl through my mp3s to find it

edit: ok so Im bored at work, its Szamár Madár from the album Csillag Allat Szuletet

-

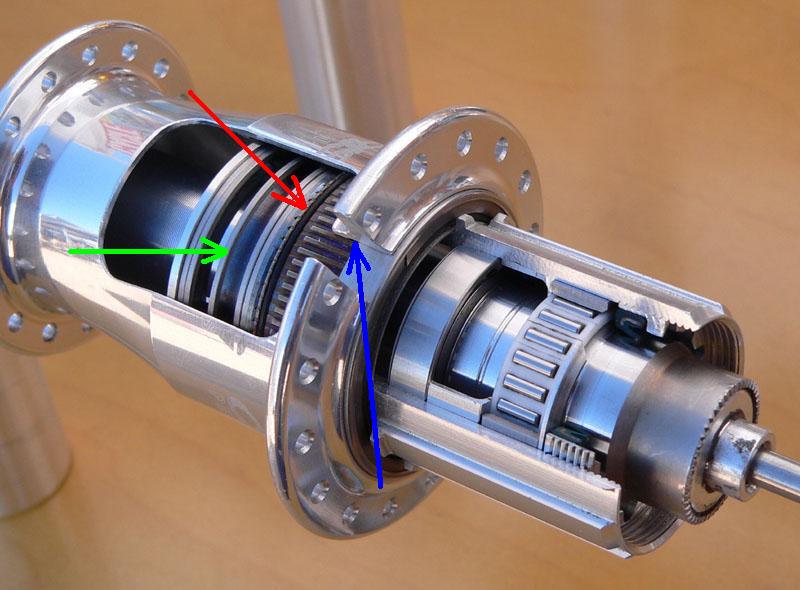

The blue arrow is just the outside of the driven ring, that's just how it's pressed into the hub shell. You can't see the helical spined bit on that photo.

Yeah I meant to say that the helical spline is inside that bit :$

Those grooves, as you say, are only there to transmit the torque through to the hubshell, alot of intricate machining in a king hub

-

The Chris King has two plates with radially toothed faces that push against each other with one turning with the hub and the other with the freehub. The helical gear bit you can see is the edge of the plate that turns with the freehub, so pedalling forces act to push the washers together more firmly. I haven't pulled one of these apart though, so can't say for certain. The picture is class for the expensive shinyness factor alone anyway.

Thats near enough right

I think.....

Red arrow is the ring drive teeth/rings.

Green arrow is the spring.

Blue arrow is where the helical bit is in the hub shell.

edit: and a photo of a stripped king hub.

-

I cheated and learnt how the ring drive works when I took it apart and serviced it after buying my discotech hub from ben travis

Mechanical design engineer with a very inquisitive mind - have to take things apart to find out how they work, occasionally the still work after Ive put them back together aswell

-

shame it doesnt have a price for it though...

does anyone have apicture of a chris king hub cut away..as i have no idea what one looks like to be honest

Tadaaa!

You cant really see how it works from that photo but it has a helical spline inside the hub shell and a sprung ring driver that slides inside the driveshell. When you pedal forwards the ring driver slides inside the hub along the helical spline and engages the ratchet tooth ring that is attached to the hubshell. When you stop putting force through the drive shell the spring forces the drive rings apart and the ratchet disengages. The high engagement is due to the number of teeth on the ratchet.

This means that the more force you put into the rotation the harder it grips - kings will only slip if the preload is set incorrectly or its not bedded or serviced in properly

-

Given that steve@heatsink already does a bash to fit the middleburns it should be pretty simple for him to modify the design to fit a FFW

Time is the major issue though

-

No reason why you can use middleburns on a mod, just cant use a FFW setup and normal mod gearing - if you use a king rear though get a heatsink bash for them and youre laughing

That said, Im sure if you talk nicely to someone they would probably be able to manufacture a FFW adaptor for middleburns

-

Done

-

WILL A MODORATOR DELETE MY ACCOUNT PLEASE. BEEN WAITING AGES FOR VALIDATION BUT THIS SHITTY VALIDTION IS A LOAD OF SHIT!!!

Or youre just incapable of typing a few simple meaningful and useful sentences?

-

Why not use a stock middleburn bash, get it machined and put a 20t on there?

-

Pisspots tend to protect more around the ears and back of the head/neck because the plastic shell extends further down

-

Id rather fund the british engineering industry and buy middleburns, stronger and british

Plus you get a decent warranty on them and none of the machined slightly wrong bollocks

-

I run between 15-20 psi and mainly ride street and dont have any problems with the single ply, that said I dont go big because Im falling apart in my old age :$

-

In my experience folding (kevlar) bead is lighter but the tyre will be more prone to peel off the rim at low pressures. Folding bead tyres are usually much easier to put on than steel bead

Dual ply sidewalls are stiffer and allow lower pressures with better pinch puncture resistance, heavier though. Personally Ive never had a pinch puncture with my single ply 2.35 high roller but Im only 11 stone and 5'8".

-

Im lieing anyways, Ive a sneaking suspicion its a t bird not master - dont think its even mine but it appeared in my bike cupboard about 4 years ago

-

but they didnt change the caliper, the pads, the disc, or the lever?

Levers the same but the caliper has larger pistons, its only a matter of a couple of mm but its enough to make the difference

-

^^^ What they said, the larger piston gives a slightly spongier brake but with more bite and hold

-

Think Ive got one sitting in a cupboard, needs a brake bolt drilling and or helicoiling

Barbed Fitting Lube?

in Trials Chat

Posted

You need to have the hose sticking out the clamps otherwise when you tap the barb in it splits the hose

A drop of normal chain oil or similar on the barb will lube it fine, I wouldnt worry about the oil comtaminating your bleed, afterall oil and water dont mix (unless you add an emulsifier) and neither are compressable under magura pressures so it wont affect it